BTMS Water-Cooled Unit Classification

To meet specific scenarios and actual customer requirements (such as BCS + air conditioner, BCS + air conditioner + motor cooling, integrated thermal management with heat recovery function, etc.), our BTMS water-cooled units are available in 5KW, 8KW, 10KW, 12KW, and 16KW models.

---

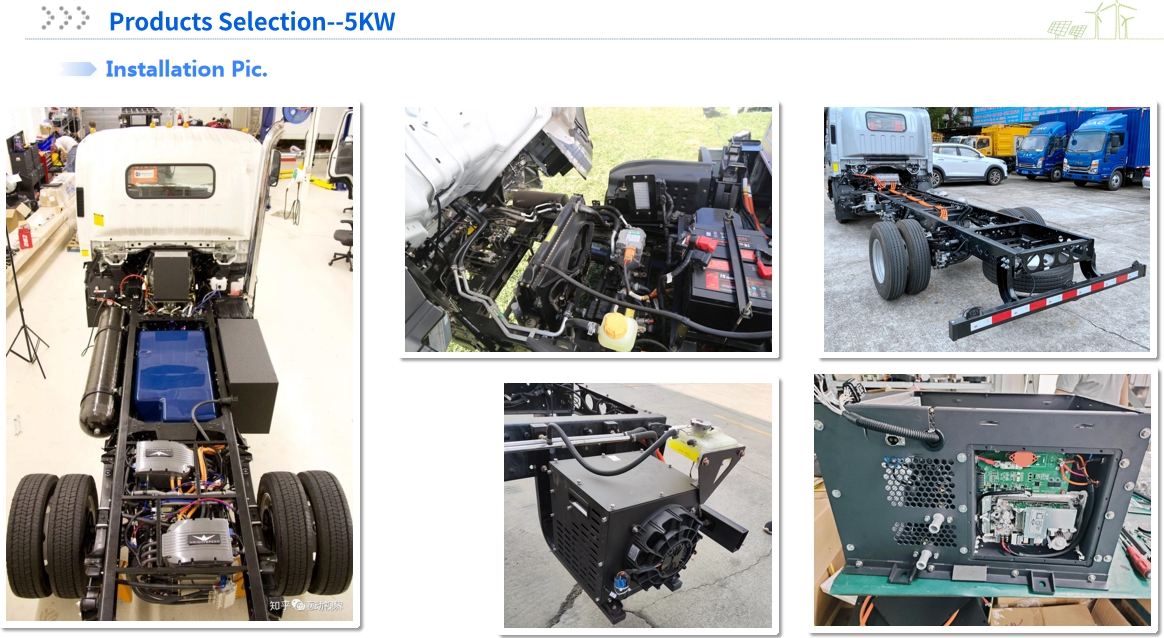

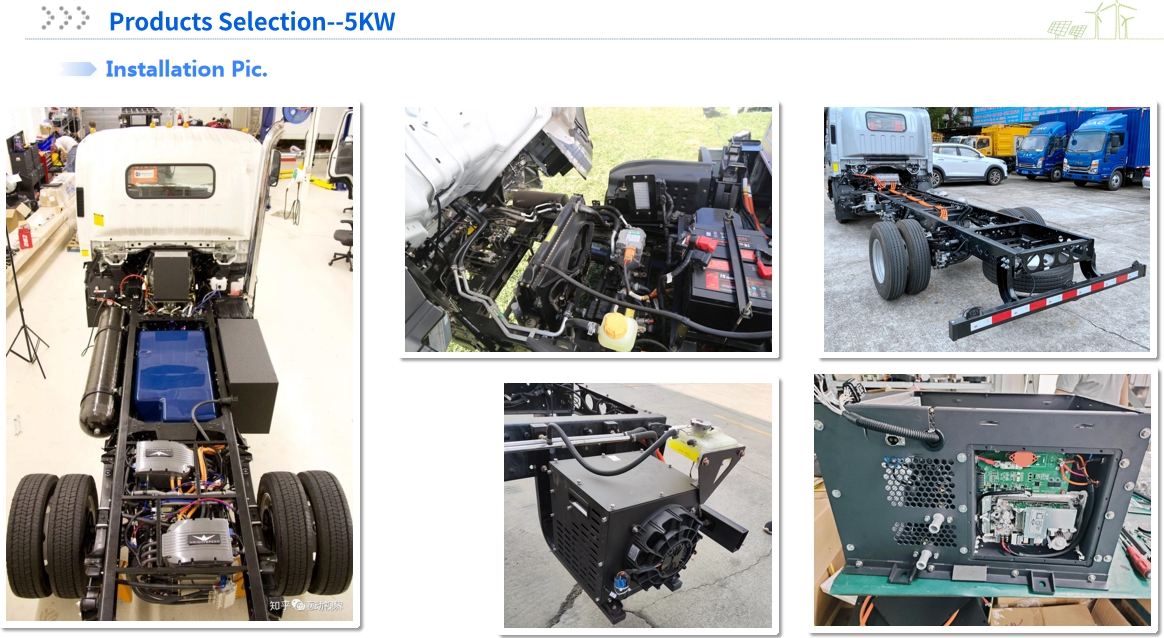

5KW Model

1. Configurable to achieve a cooling capacity of 5kW through adjustments.

2. Optional inclusion of a PTC liquid heater (6-14kW) with standby, cooling, heating, and self-circulation working modes.

3. Equipped with CAN2.0 communication.

4. Features fault self-diagnosis functionality.

5. Supports real-time power information upload.

6. Complies with Class III EMC requirements.

7. Unit weight ≤ 40kg.

---

8KW Model

1. Optional inclusion of a PTC liquid heater with standby, cooling, heating, and self-circulation working modes.

2. Capable of networked control.

3. Equipped with CAN2.0 communication.

4. Features fault self-diagnosis functionality.

5. Supports real-time power information upload.

6. Complies with Class III EMC requirements.

7. Unit weight: 50kg ± 2kg.

---

10KW Model

1. Optional inclusion of a PTC liquid heater (6-14kW) with standby, cooling, heating, and self-circulation working modes.

2. Equipped with CAN2.0 communication.

3. Features fault self-diagnosis functionality.

4. Supports real-time power information upload.

5. Complies with Class III EMC requirements.

6. Unit weight ≤ 68kg.

---

12KW Model

1. Optional inclusion of a PTC liquid heater with standby, cooling, heating, and self-circulation working modes.

2. Equipped with CAN2.0 communication.

3. Features fault self-diagnosis functionality.

4. Supports real-time power information upload.

5. Complies with Class III EMC requirements.

6. Unit weight: 110kg ± 4kg.

---

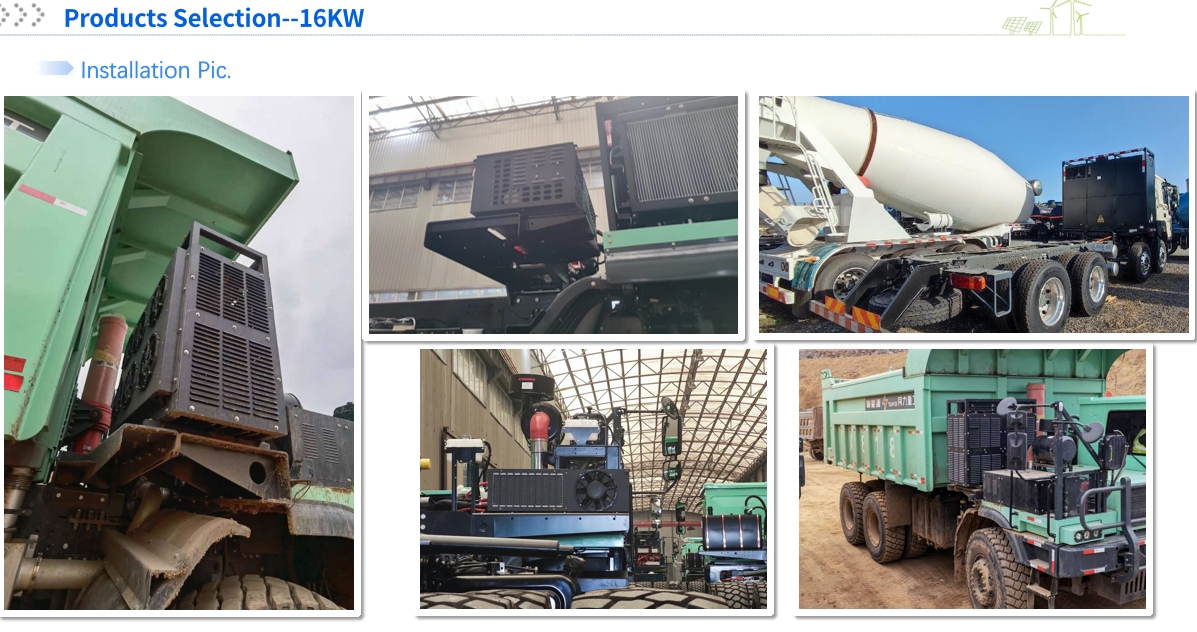

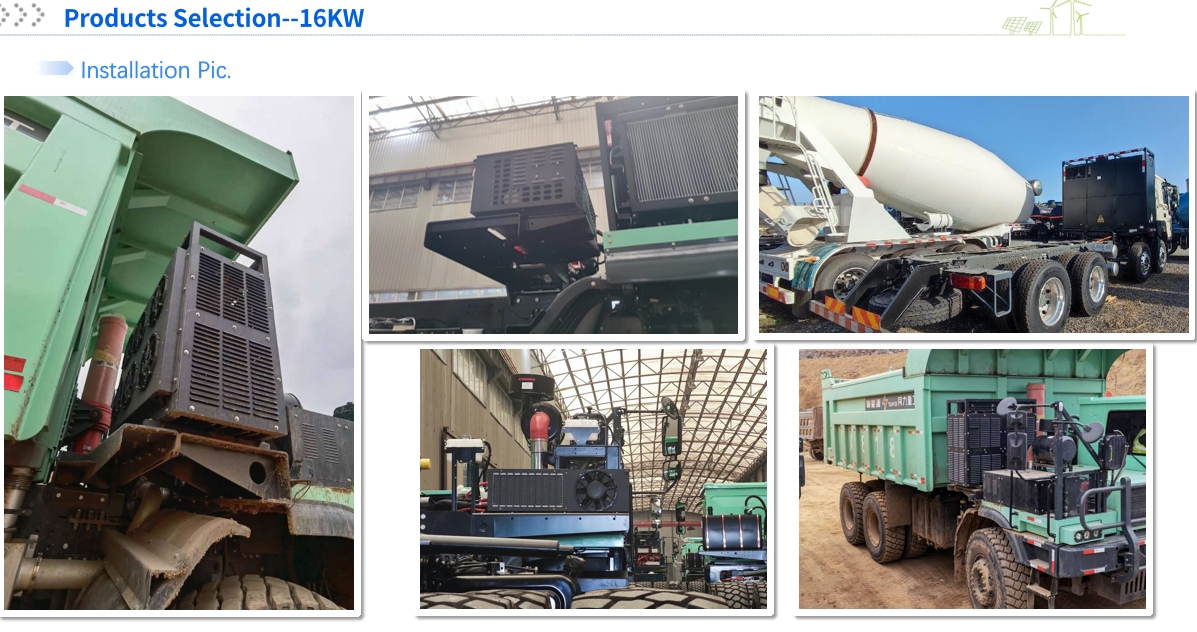

16KW Model

1. Optional inclusion of a PTC liquid heater with standby, cooling, heating, and self-circulation working modes.

2. Equipped with CAN2.0 communication.

3. Features fault self-diagnosis functionality.

4. Supports real-time power information upload.

5. Complies with Class III EMC requirements.

6. Unit weight ≤ 110kg.

---